Exploring the Field of Precision Mechanical Processing and Custom Machining

Precision mechanical processing is one of the key industries, playing a crucial role in the development of various manufacturing sectors. With the support of advanced technologies such as CNC machines, precision machining techniques enable the production of compact, highly accurate components that meet a wide range of customer demands.

Custom machining is a form of processing based on technical specifications provided by the customer. This process requires the coordination of skilled technical teams, modern machinery, and strict quality control procedures. As a result, customers receive products that perfectly match their actual usage requirements.

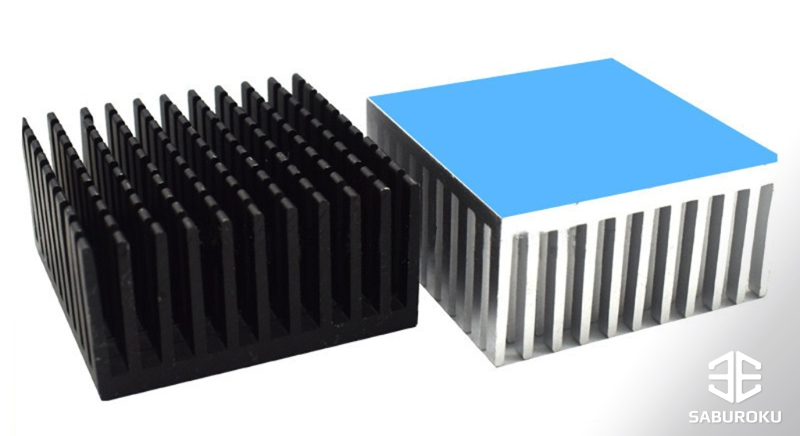

Heat sink aluminum is a specialized material used to dissipate heat from devices, helping maintain performance and extend the lifespan of electronic systems and machinery. Due to its excellent thermal conductivity, lightweight nature, and high durability, aluminum is an ideal choice in the manufacturing industry for electronic components.

Cooling systems for computers, CPUs, and GPUs.

Used in LED lighting products.

Plays a crucial role in the automotive industry and industrial equipment.

High thermal conductivity: Aluminum efficiently conducts heat, allowing rapid heat transfer from devices to the environment.

Lightweight: Significantly lighter than other metals, reducing the overall weight of the product.

Corrosion resistance: Thanks to its natural oxide layer, aluminum withstands harsh environmental conditions.

Flexibility: Easy to machine, shape, and assemble according to specific technical requirements.

SABUROKU-36 takes pride in being a leading provider of heat sink aluminum machining with a modern and efficient process:

Technical Consultation: Our team of engineers assists customers in designing and selecting the most optimal solutions.

Precision CNC Machining: Advanced CNC machines are used to shape heat sink aluminum with exceptional accuracy.

Quality Inspection: Every product undergoes strict quality control to meet international standards.

Fin-type heat sinks: Used in power supplies and telecommunications equipment.

Tube-type heat sinks: Applied in transformers and industrial motors.

Custom-designed heat sinks: Tailored to meet specific customer requirements.

Don't hesitate to reach out for consultation and a detailed quotation:

Factory Address: No. 26, Tien Phong 16 Street, BW Sup Industrial Park, Hoa Phu Ward, Thu Dau Mot, Binh Duong.

Branch Office: No. 55, Street 16, Quarter 4, An Phu Ward, Thu Duc City, Ho Chi Minh City.

Hotline: 0909 723 443

Email: anhluong@saburoku-36.com

Website: www.saburoku-36.com

Let SABUROKU-36 be your trusted partner in delivering high-quality heat sink aluminum products that meet all technical requirements!