In modern industry, precision machining according to custom requirements plays a vital role in manufacturing high-precision products for various fields such as automotive, electronics, medical, aerospace, and other industries. Precision machining helps create machine parts, components, and equipment that offer high durability and optimal performance, meeting stringent technical standards.

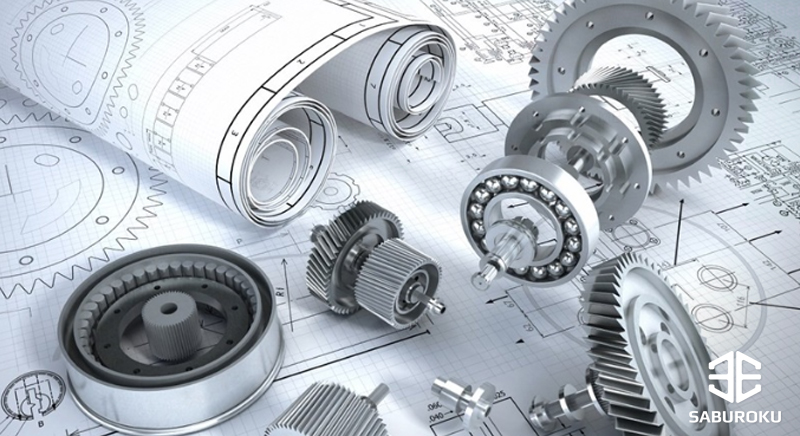

Precision machining is the process of manufacturing parts and components from raw materials through various machining operations such as turning, milling, grinding, cutting, and other advanced technologies. The goal of precision machining is to create products with extremely high dimensions, shapes, and precision, ensuring that the product meets technical and quality requirements.

Precision machining according to custom requirements can be applied to manufacturing complex machine parts, especially in industries that demand high precision, such as machinery, electronics, automotive, aerospace, and medical sectors. This requires service providers to have advanced technology, modern machinery, and a highly skilled technical team.

To manufacture parts with high precision, modern machining technologies and advanced technical processes are essential. Common precision machining technologies include:

CNC Machining (Computer Numerical Control): This is an automated machining technology that allows for the production of parts with high precision and flexible programming capabilities. CNC machines can perform operations such as turning, milling, drilling, and grinding with fast speeds and absolute accuracy.

EDM Machining (Electrical Discharge Machining): This uses electrical discharges to create small holes or complex shapes in hard materials such as stainless steel or titanium.

Grinding: This process uses abrasive stones to clean and machine parts with high precision, especially for parts requiring smooth surfaces without defects.

Turning and Milling: Basic but important machining methods that help create both simple and complex parts with high precision.

Precision machining according to custom requirements offers many benefits to manufacturing businesses, especially in industries that require products with absolute precision. Some of the key benefits include:

Ensuring product quality: With advanced technology and precise machining processes, the resulting products will meet size and quality requirements, helping businesses avoid errors in the final products.

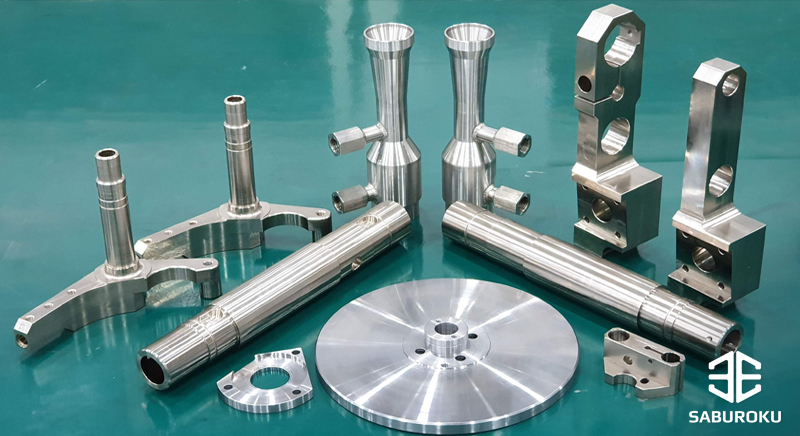

Increased flexibility in production: Companies providing precision machining services can produce parts according to customer specifications, from the smallest components to complex assemblies, saving time and costs for businesses.

Meeting technical standards: Precision machining ensures that products meet international standards, thereby enhancing the company's reputation and competitiveness in the market.

Saburoku is proud to be one of the leading companies in the field of precision machining according to custom requirements, offering machining services for parts with high precision for various industries. With a team of experienced technicians and modern machinery, Saburoku is committed to delivering high-quality products that meet all technical requirements and international standards.

Contact information:

Saburoku is committed to providing precision machining services according to custom requirements, helping businesses improve production efficiency and ensure product quality.