In the field of precision mechanical processing, extruded aluminum machining has become one of the most prominent sectors due to its flexibility, durability, and wide range of applications. Extruded aluminum is widely used in various industries, including automotive, electronics, construction, and consumer products. This article provides an overview of extruded aluminum machining, its manufacturing process, and its applications.

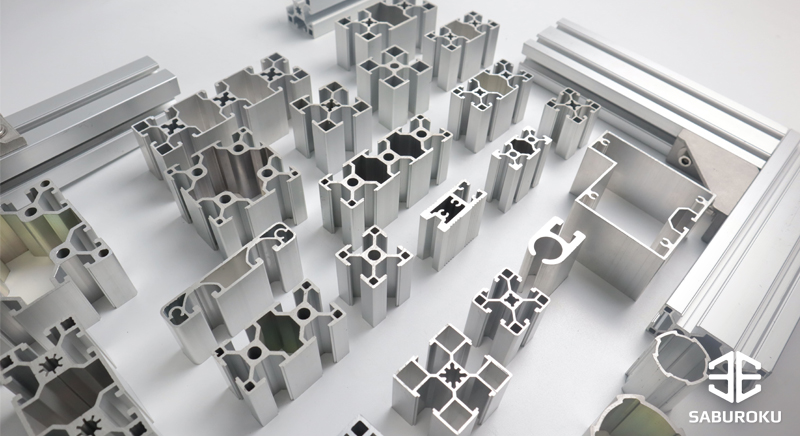

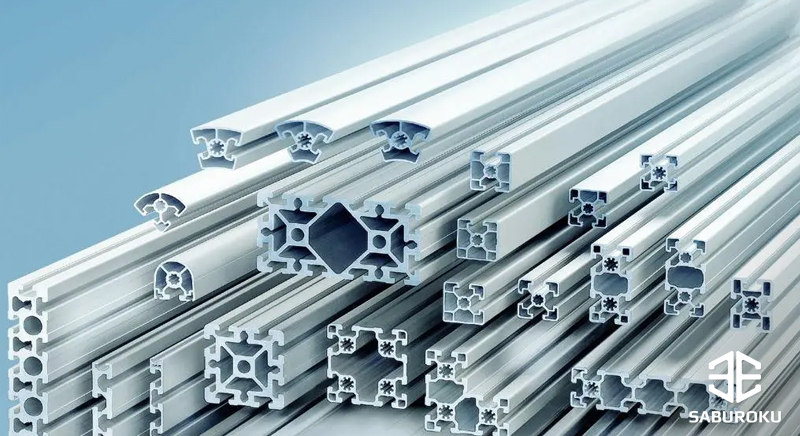

Extruded aluminum refers to aluminum that is manufactured into bars, tubes, or other structural shapes with predetermined dimensions and designs. This process is typically carried out through hot extrusion, producing highly durable products with excellent load-bearing capacity. Extruded aluminum can be cut, bent, drilled, ground, or further machined to meet the specific technical requirements of different products.

The machining of extruded aluminum involves multiple stages, from material selection and mechanical processing to quality inspection. The key steps in this process include:

The raw material for extruded aluminum machining consists of high-quality aluminum alloy bars, which are cut into specific lengths as required before entering the production line.

Once the raw material is ready, the aluminum components undergo precision machining using CNC machines, drilling machines, laser cutters, lathes, and other specialized equipment. This stage includes:

Cutting and shaping the aluminum to the desired dimensions.

Drilling and hole-making for assembly or design specifications.

Bending and edge finishing to ensure smooth surfaces and precise angles.

Surface finishing is a crucial step that enhances both the technical performance and aesthetic quality of the final product. Common finishing techniques include:

Anodizing (electrochemical oxidation) for corrosion resistance.

Powder coating for durability and color customization.

Polishing for a smooth and refined appearance.

Every extruded aluminum product undergoes strict quality control to ensure compliance with technical standards. Key tests include:

Dimensional measurement to check for accuracy.

Hardness and strength testing to ensure durability.

Corrosion resistance assessment for longevity in various environments.

Extruded aluminum is widely used across various industries due to its strength, lightweight nature, and versatility:

Construction Industry: Used in window frames, glass partitions, and structural components. Its high load-bearing capacity and lightweight properties make it an ideal material for modern buildings.

Automotive Industry: Found in car frames, interior, and exterior decorative parts, contributing to weight reduction while maintaining strength.

Electronics Industry: Essential in heat sinks, computer hardware, and mobile device casings, thanks to its excellent thermal conductivity.

Medical Equipment Manufacturing: Used in hospital beds, operating room equipment, and other devices requiring durability and lightweight properties.

Extruded aluminum machining offers numerous advantages in terms of technical performance, cost efficiency, and production effectiveness:

High durability: Extruded aluminum has excellent corrosion resistance, ensuring long-lasting performance in various environments.

Lightweight: Despite its high strength, aluminum is a lightweight material, reducing transportation costs and simplifying installation.

Cost savings: The use of extruded aluminum minimizes the need for extensive reprocessing, leading to lower production costs and shorter lead times.

Aesthetic appeal: Machined extruded aluminum products are not only functional but also visually appealing, making them suitable for a wide range of applications.

SABUROKU specializes in high-quality extruded aluminum machining, meeting customers’ demands for precision, durability, and fast delivery. With an experienced technical team and state-of-the-art machinery, we are committed to providing efficient and cost-effective aluminum machining solutions.

📍 Factory Address: No. 26, Tien Phong 16 Street, BW Supply Chain City Industrial Park, Hoa Phu Ward, Thu Dau Mot City, Binh Duong Province.

🏢 Office Address: No. 55, Street 16, Quarter 4, An Phu Ward, Thu Duc City, Ho Chi Minh City.

📞 Hotline: 0909 723 443

📧 Email: anhluong@saburoku-36.com

🌐 Website: www.saburoku-36.com

We are always ready to provide expert consultation and optimal extruded aluminum machining solutions, ensuring high economic efficiency for your business. Let SABUROKU be your trusted partner!