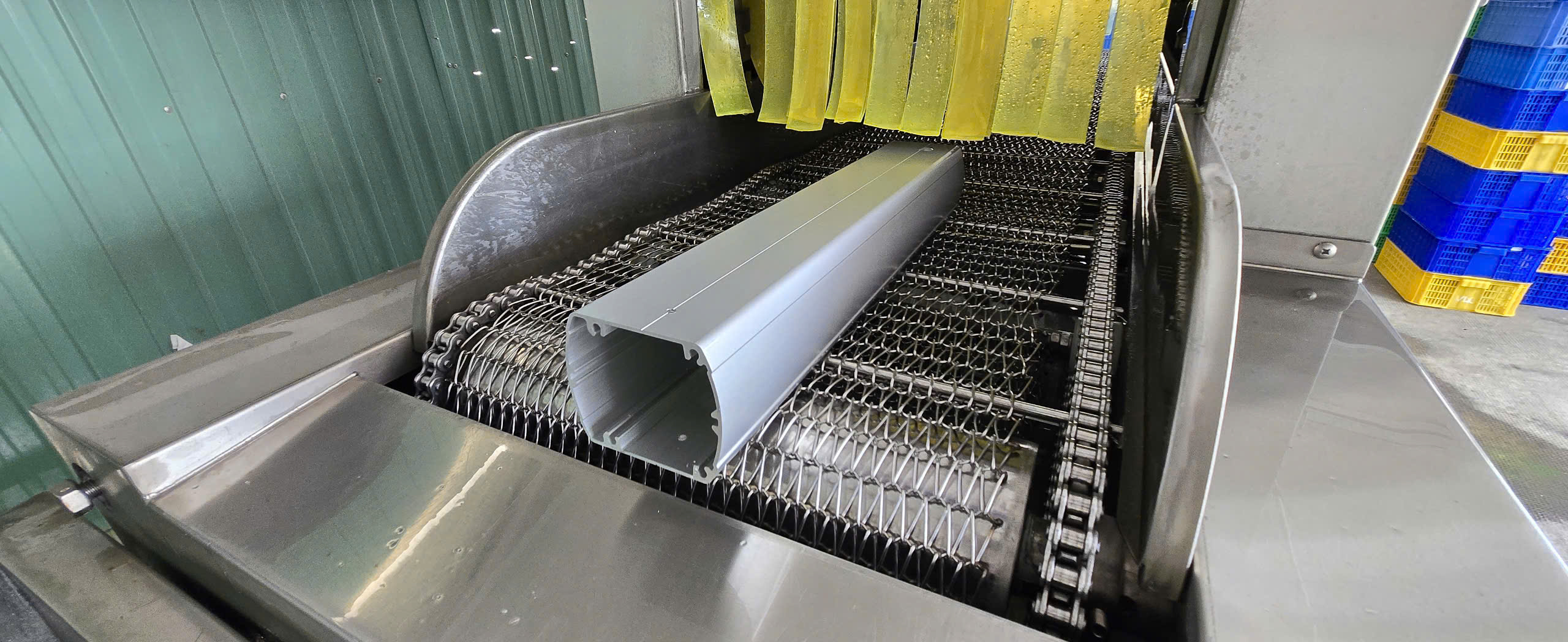

The Importance of Aluminum Heat Sinks in Robot Control Panels

What is Machining?

The concept of machining might seem unfamiliar to many people. To get a general overview, it can be understood as follows:

Machining is a process that involves stages of using machinery, equipment, machining techniques, and physical principles to create products with high precision. These are products with practical applications in activities that serve daily life and economic development. In English, it is called "Machining".

In Vietnam, there are quite a few precision machining companies for customers to choose from. However, the machinery systems, quality, and expertise of the engineering and mechanical technician teams differ significantly from one company to another. This very fact leads to disparities in the quality of the manufactured mechanical products.

Therefore, selecting a reputable machining workshop is crucial to ensure the resulting products are always of the best quality at the most reasonable cost.

You can easily encounter products of the machining industry in every aspect of life, from the vehicles you drive and the machinery you operate to household appliances and medical equipment.

Precision Machining According to Requirements is the process of fabricating and manufacturing mechanical components or products through the use of machining methods such as cutting, milling, turning, planing, grinding, drilling, and many others. This process can be performed manually or via machinery to create mechanical parts with high precision.

Precision machined products can be used in various industries such as automotive manufacturing, aerospace, oil and gas, medical devices, electronic equipment, and many other fields. During the machining process, mechanical engineers and technicians design, program, and control the machining equipment to produce high-precision, high-quality products.

Machined products are those created from materials such as iron, steel, stainless steel, alloys, copper, aluminum, plastic, etc.

To achieve high precision in the machining process, manufacturers often utilize modern machinery, technology, and equipment such as various types of CNC machines, lathes, milling machines, and many other machining tools. These processes and technologies help enhance productivity, precision, and the durability of the mechanical products.

It is these stringent requirements for precision in tolerances and aesthetics that demand businesses invest in modern equipment and a professional, skilled workforce. However, not every company has the sufficient resources to adequately equip themselves with these. Therefore, businesses often collaborate with precision machining workshops that operate on-demand to have their parts manufactured.

Mechanical processing:

SABUROKU Company - Mechanical Machining Services in Ho Chi Minh City & Binh Duong

SABUROKU company provides precision machining services in Ho Chi Minh City and Binh Duong. We specialize in the design, machining, and manufacturing of stamping dies, and the production of various types of industrial machine parts used across numerous fields. Our core expertise lies in medical-grade aluminum machining.

Saburoku boasts a highly qualified and experienced workforce with many years in the industry. We are always ready to support and advise our clients throughout the entire machining process—from design to material selection—helping you save costs, enhance product quality, and optimize performance.

Every product we machine is carefully inspected before being delivered to the customer.

Contact us directly:

Factory Address: Workshop No. 26, Tien Phong 16 Street, BW Sup Industrial Park, Hoa Phu Ward, Thu Dau Mot City, Binh Duong Province.

Branch Office: No. 55, Street 16, Block 4, An Phu Ward, Thu Duc City, Ho Chi Minh City.

Hotline: 0909 723 443

Email: anhluong@saburoku-36.com

Website: www.saburoku-36.com